-

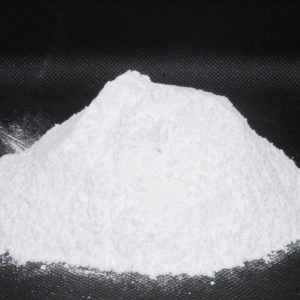

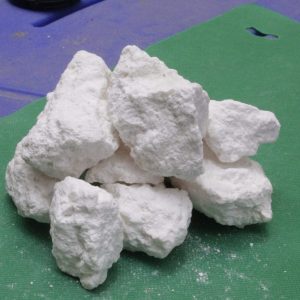

Limestone is one of the most widely used industrial minerals due to its abundance, versatility, and chemical properties. It is primarily composed of calcium carbonate and is found in massive sedimentary rock formations around the world. Industrial-grade limestone is carefully selected for its purity, particle size, and mineral content to meet the requirements of specific applications.

-

Limestone plays a central role in the manufacturing of cement, where it is heated with clay or shale to produce clinker, the key component of Portland cement. It is also used extensively in the production of lime (quicklime and hydrated lime), which serves as a fundamental material in steelmaking, water treatment, flue gas desulfurization, and other chemical processes.

-

In the steel industry, limestone acts as a flux to remove impurities such as silica, phosphorus, and sulfur from molten iron. This improves the quality of the steel and enhances furnace efficiency. Limestone is also essential in non-metal industries such as glass manufacturing, paper production, and paint and coatings, where it functions as a filler, pH buffer, or stabilizer.

-

Environmental applications of limestone have grown significantly in recent decades. It is used to neutralize acidic soils in agriculture and to control emissions from power plants by capturing sulfur dioxide in scrubber systems. Crushed limestone is also employed in water purification and waste treatment processes, helping to maintain ecological balance and regulatory compliance.

-

From heavy industry to environmental management, limestone's importance lies in its adaptability, affordability, and reliable performance. Its diverse roles across sectors make it a cornerstone material in both traditional manufacturing and modern sustainable practices, underlining its value in industrial development worldwide.

Uses of Limestone in Industry

Limestone is the primary raw material in cement production. It is heated with clay to form clinker, which is then ground to produce Portland cement—used in everything from buildings to infrastructure.

In steel making, limestone acts as a flux to remove impurities such as silica and sulfur from molten iron, improving the quality of the finished steel and enhancing furnace efficiency.

Limestone is calcined to produce quicklime (CaO) and hydrated lime (Ca(OH)₂), both of which are essential in industries like construction, chemical manufacturing, and agriculture.

Limestone is used in power plants to capture sulfur dioxide emissions. In wet scrubber systems, it reacts with the gas to form gypsum, reducing air pollution and meeting environmental standards.

Ground limestone (agricultural lime) is applied to acidic soils to raise pH levels, improving nutrient availability and crop performance in farming and land reclamation.

Finely ground limestone is used as a filler in paper, plastics, paints, and coatings. It enhances product consistency, improves surface finish, and reduces production costs.